Garage Floor

Epoxy Coating

When it comes to epoxy garage floors people all across America have been installing epoxy coatings because they offer so many beautiful and strong benefits. Epoxy garage floors should always be installed by a professional group of technicians for reasons such as:

- Most companies offer a long-standing warranty and if something goes wrong during the installation process, they will fix it.

- Concrete floors need to be thoroughly prepped before applying the epoxy coating, so renting or buying the proper machinery and appliances becomes very expensive.

- There is a larger variety when choosing from a professional technician. There are special colors, designs, and textures that can be chosen from.

There are ways to install epoxy garage floor coatings on your own, it is not highly recommended or encouraged by professional epoxy coating companies simply because a professional who makes these installations their life’s work will complete the job much better. But if you insist on installing it on your own, follow some professional tips below:

- Thoroughly read the instructions. This might seem like a pretty standard thing to do but we all have a tendency to skip ahead to the good part, in this case, we want to get to the installation part; however, there are important steps that need to be taken before we begin to install.

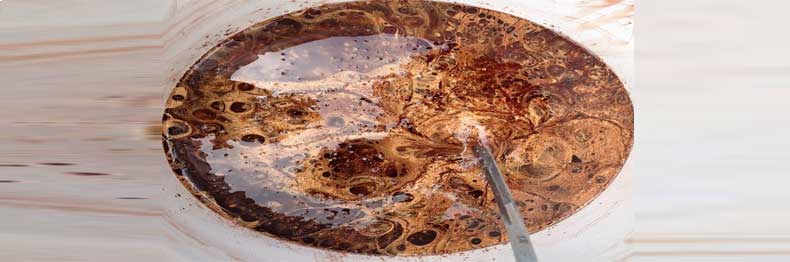

- inspect the garage floor. Don’t just look at it, really inspect it because if there are prior coatings and sealants on the floors surface your new epoxy coating will not adhere to the surface. You can test for sealers and coatings by either spilling water on the concrete and checking to see if the water was absorbed or by applying a small amount of acid and checking if the acid changes then there is no sealer but if the acid simply sits on the surface then there is, in fact, a sealer that needs to be removed.

- While you inspect also note any cracks, pitted areas, or spalling that will need repairing before the epoxy coating is applied.

- Run a moisture test! We cannot stress this enough. If there is too much moisture in the concrete the epoxy will not property adhere to it. You are scanning the surface for damp spots and efflorescence, which looks like powder rising on the slab caused by excess line and salts. Testing for moisture will ensure that your concrete surface will even be able to bond with an epoxy garage floor coating.

- Clean the garage floor. Remove oil, grease, stains, vehicle fluids, and any other sealants or coatings that are present.

- You have to open your concretes pores. This part in the process is just as important as the rest because missing this one will mean your coating washes right off of your concrete. You can either grind the surface down or acid etches it. Grinding is the preferred method by professionals here, however, it is crucial not to forget the fact that you need to clean off the surface after grinding. Remove all fragments and dust brought on by the grinding. Acid etching the garage takes more time and you will need at least 24 hours for the surface to completely dry.

- Repairing the cracks and any other issues found during your inspection is up now! Use contraction joints to ensure a seamless finish. If you have extensive repairs that need to be addressed there are different types of epoxy coatings that hide flaws and blemishes.

- The best temperature to apply your epoxy garage floor coating in is between 70. And 80 degrees. If the humidity is forecasted to be above 85% postpone your installation.

- Mix the coating as instructed by the manufacturers

- Apply the first coating and take steps to ensure critters are not drying in your coating.

- The second coat depends on your manufacturer’s instructions and what you’re looking for.

Tolls that will be required (you may need less or more depending on your garage floor)

- Tarp

- Speed drill

- Mixing paddle

- Calibrated containers

- Pails

- Latex gloves

- Rags

- Acetone

- Rollers of varying sizes

- Threaded pole extension

- Spiked shoes

- Drywall taping knife

- Painters tape

- Cheap clothes